Les quatre critères les plus importants pour choisir un écouvillon pour la validation du nettoyage

2022-09-06

Dans la fabrication pharmaceutique, le produit ne doit pas être contaminé par un produit précédent ni par l'agent de nettoyage utilisé pour le nettoyage de l'équipement.

To verify the cleaning process it is validated by taking the sample from various parts of cleaned equipment that is to be used in the manufacturing process and these samples are analyzed for contamination.

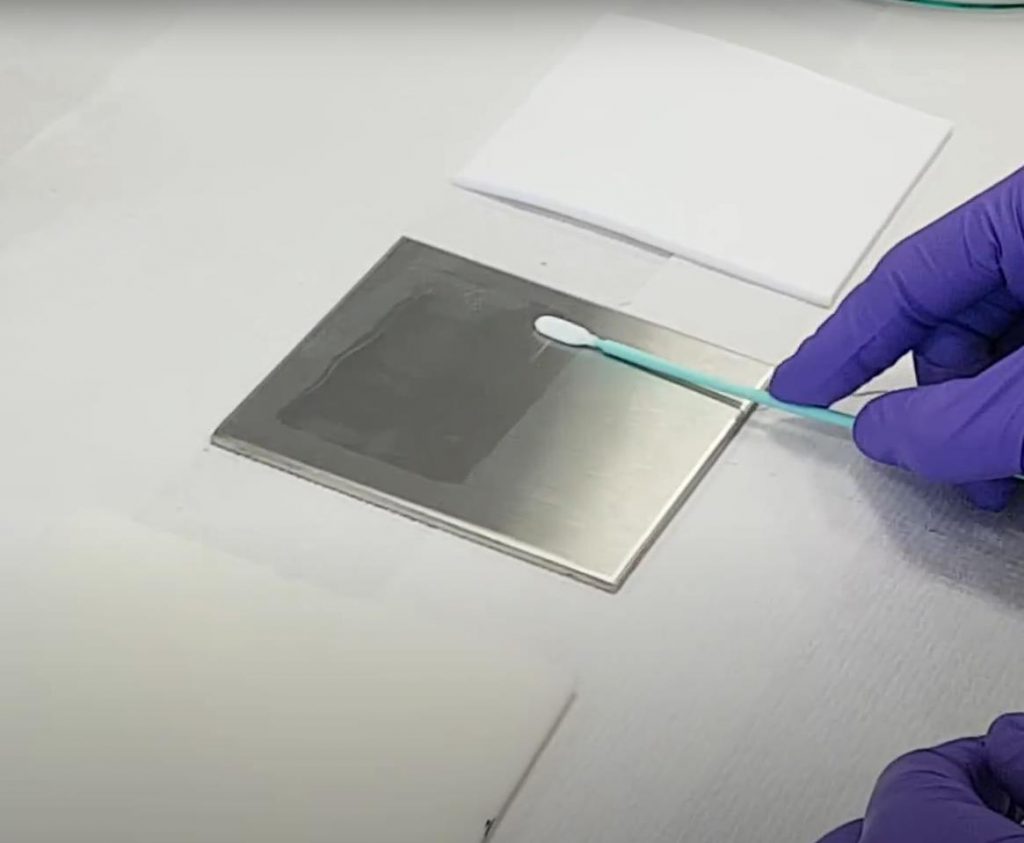

Swabs are used to take a sample from the cleaned equipment for analysis. Contaminants of previous product or cleaning agent residues are eluted from the swab. The analysis is done by HPLC or GC to determine the amount of residues. TOC analyzer can also be used to determine all the oxidizable carbon compounds.

To get the accurate results, it is required to use the correct swab to take the sample because swab is the main component that has the highest chances of error and may result in the inaccurate cleaning validation. Following are the four most important criteria to choose a swab for cleaning validation.

Minimal Extractable Interferences

Extractable interferences are the residues of the swab itself. The contaminants extracted from the swab during its use should be the minimum. These are the contaminants in the blank swab i.e. swab in the solvent used to take a sample.

Solvent Compatibility

A variety of solvents are used for swab sampling according to the residues of the previous products.Therefore, the swab must not have any chemical reaction with the solvent used for sampling because this may alter the actual cleaning validation results. Par conséquent, swab must be compatible especially with the solvent to be used for the swabbing.

High Recovery Rate

Recovery rate is the percentage of the released amount of the sampled content. A swab doesn’t release whole swabbed content but it should release the maximum that it can. Minimum 60 % recovery rate is acceptable but the higher recovery rate is better.

Low Particle Generation

Every swab sheds particles during its use on equipment surface and it is difficult to find a non-particle shedding swab at all. But we must select a low particle generating swab because these particles will contaminate the next product that will be manufactured on that equipment.

All the above features should be considered before selecting the swab for cleaning validation sampling.You may add more things in this list like the size of the swab, swab must be sufficient in size to cover the sampling area by 5-10 écouvillonnage. A bigger swab will be able to hold more material from the sampling surface.

A swab plays an important role in successful cleaning validation. Hence swab for sampling must be selected carefully because it can ruin all your validation activit

La source: Pharmaceutical Guidelines